Hydraulic Rod & Industrial Roll Repair Services

We also specialize in rod and roll repair. Through normal wear and tear (or in some cases extreme wear and tear), a rod must be repaired before it can be ground and plated to its specification.

HTCP’s rod and roll repair capabilities include:

- External grinding capability

- TIG Welding repair

- MIG Welding repair

- Magnaflux inspection of cylinders upon request

- Inspection reports may be completed upon request

- Following completion of the repair and plating process, a resulting chrome hardness of 68-72 Rockwell

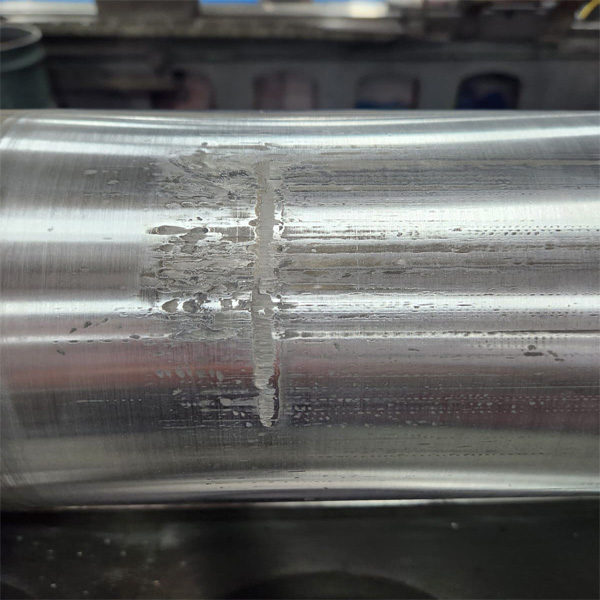

Repairs we commonly perform:

- Rust pitting from rod corrosion

- “Saddles” worn into rod from common wear areas

- Small-diameter rods with bends near the middle

- Deeper damaged areas in the chrome layer or base metal due to extreme wear during use or improper disassembly of the cylinder

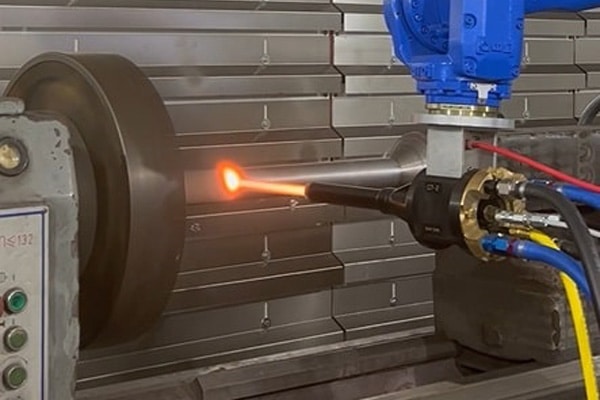

For extreme wear on heavy rods and rolls, we offer a like-new repair option via submerged arc welding

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.